One of the main limitations for the wide diffusion of sorption systems, either as stand-alone and in hybrid configurations, is the low heat transfer inside the adsorber, as well as the low volumetric cooling power.

In this context, HYBUILD partners (CNR ITAE, AKG, Fahrenheit and Mikrometal) have just released a new scientific paper which reports the experimental activity on four different advanced configurations for the adsorber, based on microchannel heat exchangers where the gap between the channels is filled with porous structures where zeotypes of SAPO-34 family were synthetized.

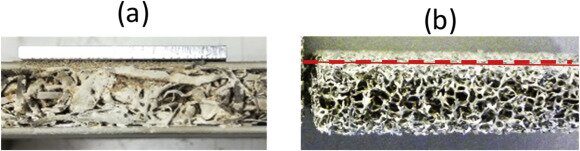

The porous structures evaluated are high-density fins, two different aluminium foams and compressed chips from the waste of aluminium machining. The sorption dynamic and cooling power density of each structure were measured through a Gravimetric Large Temperature Jump testing apparatus.

The results obtained showed that the best-performing configuration is the one with high-density fins, that, for a 90/30/20 °C cycle showed a Specific Cooling Power up to 1.1 kW/kg. The other structures exhibit a much slower adsorption process, corresponding to power densities of about 0.3 kW/kg. The results were used for sizing a full-scale adsorber, whose expected Volumetric Cooling Power is 500 kW/m3.

Read the full paper here.